Single-Sheet Technology

Single-Sheet Thermoforming

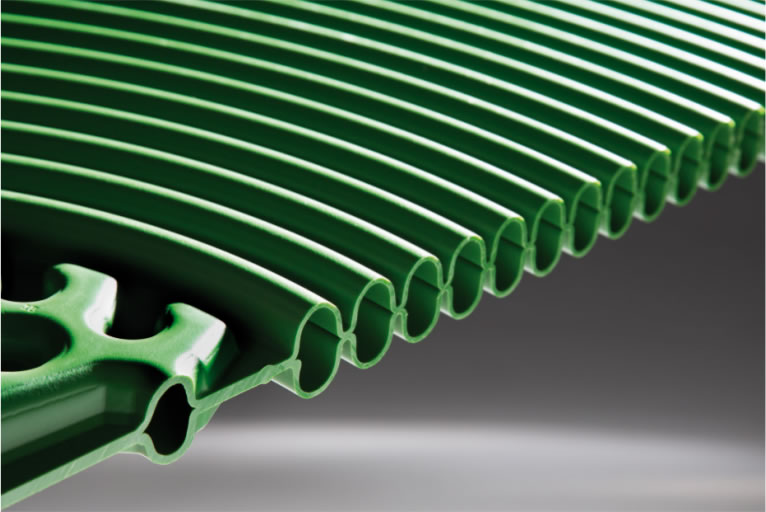

Thermoformed parts produced by single-sheet technology for various applications and industries make almost limitless individuality of design, material and form size possible.

The DUROtherm Group has more than 28 thermoforming units altogether for the production of single-sheet thermoformed parts in various sizes from major suppliers. Apart from vast production capacities, this big machinery has the advantage that each order can be produced on a machine suited for the respective thermoformed part. But even as regards the sizes of forms DUROtherm is a decisive step ahead of the competition: Huge parts up to a size of 4200 x 2500 mm can be produced in one of the biggest thermoforming plants for contract manufacturing in Europe.

The Single-Sheet Process

In the single-sheet process a firmly clamped plastic sheet is first heated on both sides. While the mould is moving upwards compressed air is used to pre-stretch the hot sheet. The air between the mould and the sheet of plastic is then evacuated and atmospheric pressure causes the sheet to conform to the mould.

Afterwards a cooling fan cools the thermoformed component below the solidification point of the plastic. A flow of compressed air releases the finished thermoformed part from the mould.