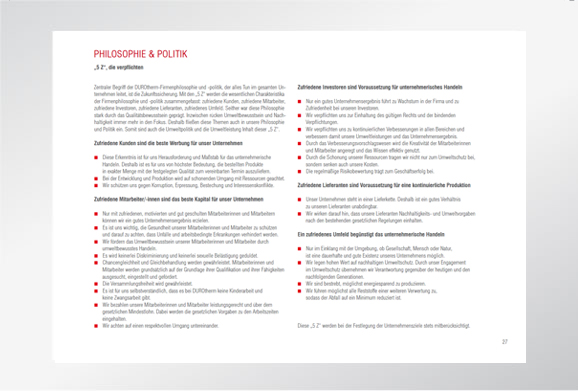

Philosophy

Our Ultimate Goal Is to Satisfy All

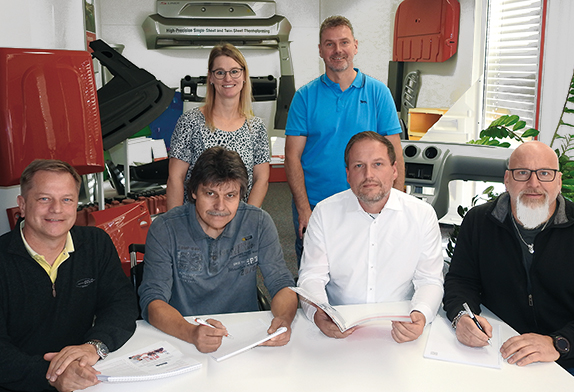

Manager Partner Dipl. Wirt.-Ing. (FH) Andreas Hartl

Our greatest concerns are to fully satisfy our customers in all areas of cooperation and the respectful use of natural resources. Our strict focus on customer requirements is fulfilled by well-founded advice and technically perfect moulded parts, but also by high flexibility and high reliability. Our friendly, helpful and well-trained staff is essential for the achievement of this goal.

DUROtherm has always been an owner-operated company. This results in vertical structures of responsibility and decision, which are fertile grounds for high levels of performance and customer orientation. Our cooperative relationship with customers, suppliers and employees inspires mutual confidence and is the basis of a successful and lasting cooperation.

Highest quality standards combined with the spirit of partnership and fairness are success factors, which make DUROtherm a powerful partner – today and in the future.